Overview

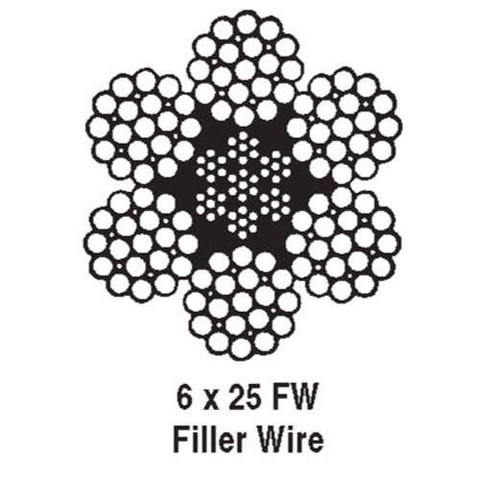

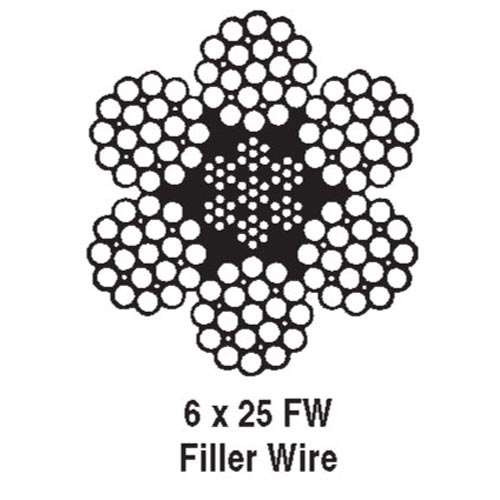

6 X 25 CLASSIFICATION The 6 x 19 Seale has outer wires larger than 6 x 21 FW, 6 x 25 FW or 6 x 26 WS, and therefore its resistance to abrasion is increased but its fatigue resistance is decreased; it is a good rope to withstand abrasion or crushing on the drum. Outer wires of 6 x 21 FW are larger and fewer than those of 6 x 25 FW, which means better resistance to abrasion but somewhat less resistance to bending fatigue, making it a good choice where abrasive wear is accompanied by moderate bending. A 6 x 25 FW has good balance between resistance to abrasion and fatigue resistance, and is often considered the work horse of wire ropes, used for more purposes than any other construction. The 6 x 26 WS is a compact construction with solid support for the wires, hence it has a high resistance to crushing. Resistance.to abrasion is the same as 6 x 21 FW. Number and relative size of inner wires add to stability of strands, and give fatigue resistance comparable to 6 x 25 FW. It is a good choice where both abrasion resistance and fatigue resistance are required.